.png)

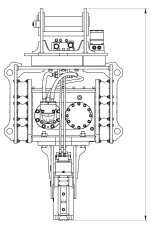

Motor

Vibro isolating rubber

Hook

Electrical parts

Bearing

.png)

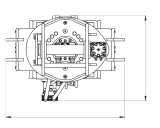

L

H

W

Control valve

_qx01.png)

_qx02.png)

.jpg)

.jpg)

※

The above specifications are subject to change without prior notice for quality

improvement.

Description

Carrier

Clamping Jaw

Frequency

Slewing Degree

Dimension (L×W×H)

Oil Flow

Operating Pressure

Weight

Hammer

Extension boom

20~28

1600

600

65

2000~2500

360

1857 × 1042 × 650

130~180

180~200

28~34

1800

700

65

2000~2500

360

1959 × 1103 × 792

170~200

200~250

33~40

1900

700

65

2000~2500

360

2016 × 1196 × 830

200~260

200~250

HVH 08

HVH 10

ton

kg

kg

mm

bpm

degree

mm

lpm

bar

HVH 14

Unit

•Lower cost of maintenance than crane hammer.

•Outstanding workability and mobility.

•Easier operate in critical regions such as chaotic section of city, bridge area

and the

vicinity of high-voltage wires than crane hammer does.

•Equipped with high-powered hydraulic piston motor and suitable bearing for high

frequency vibration.

•Install vibro isolating rubber for high frequency purpose.

•Easy connect and disconnect the hammer by the use of excavator’s breaker hydraulic lines.

•The clamping lug can handle and move construction objects easily.

•Pile driving power 20% up compared to the existing equipments.

•Sufficient wear-resistant design and 360-degree revolution.

► Feature